This week I set out to visit the Royal Exchange Theatre workshop again, and use it to my advantage, in order to choose an appropriate stain and varnish for the table. I tested several shades of wood stain on several different types and thicknesses of wood.

With the idea in mind of wanting to make the wood look more expensive and aged, the Brown Oak and Brown Mahogany stains worked the best. I also applied a satin varnish to the samples to add a sheen to the surface. One of the technicians at the workshop allowed me to cut a piece of varnished 18mm birch plywood down to the size I needed - 800mm X 450mm. I then had to sand off the varnish so that I could apply a new one and the wood would take the stain. I thought a thicker plywood than the 6mm standard one from the laser workshop would be more suitable for the table as it is heavier and more durable, so 18mm was ideal!

Problems with producing the table

After sampling on the laser cutter last week, myself and Jenny tried to book back on the machine at the next available space to engrave the 18mm plywood. However, we came across our biggest problem in this project so far - there wasn't any space left until after the deadline! Adan the technician had a cancellation that same day, so there was a slight panic to gather materials together in time for the slot he could offer us. I managed to get the wood from home and get back to the workshop in time for the session, so it was a success, although it was very heavy! On beginning the session, Adan explained that we would not be able to cut through the 18mm plywood with the laser, as the thickest it could cut through is 6mm, although we would be able to engrave onto it still. We had to alter the design quickly in order to finish it within our given slot. In the short notice of being able to use the laser cutter, we didn't have any slate with us to engrave into for the centre of the table. We have had to change the design slightly so that only one 10cmX10cm tile will fit in the centre now - it is not ideal, and we would have liked more time on the machine to engrave better designs onto the slates, but there was a long waiting list after our session for cancellations, so we had to make the most out of a bad situation. Adan did however suggest that we could design the hole for the centre of the wood and he would be able to create a rebate for the slate to sit in using the CNC Router, making the surface flat and appropriate for use. I plan to revisit the Royal Exchange Theatre Workshop this week to finish off the table top, staining and varnishing it as planned. We will then find a way to secure the slate in place in the centre of the wood next week.

Stained Wood

Additional Work

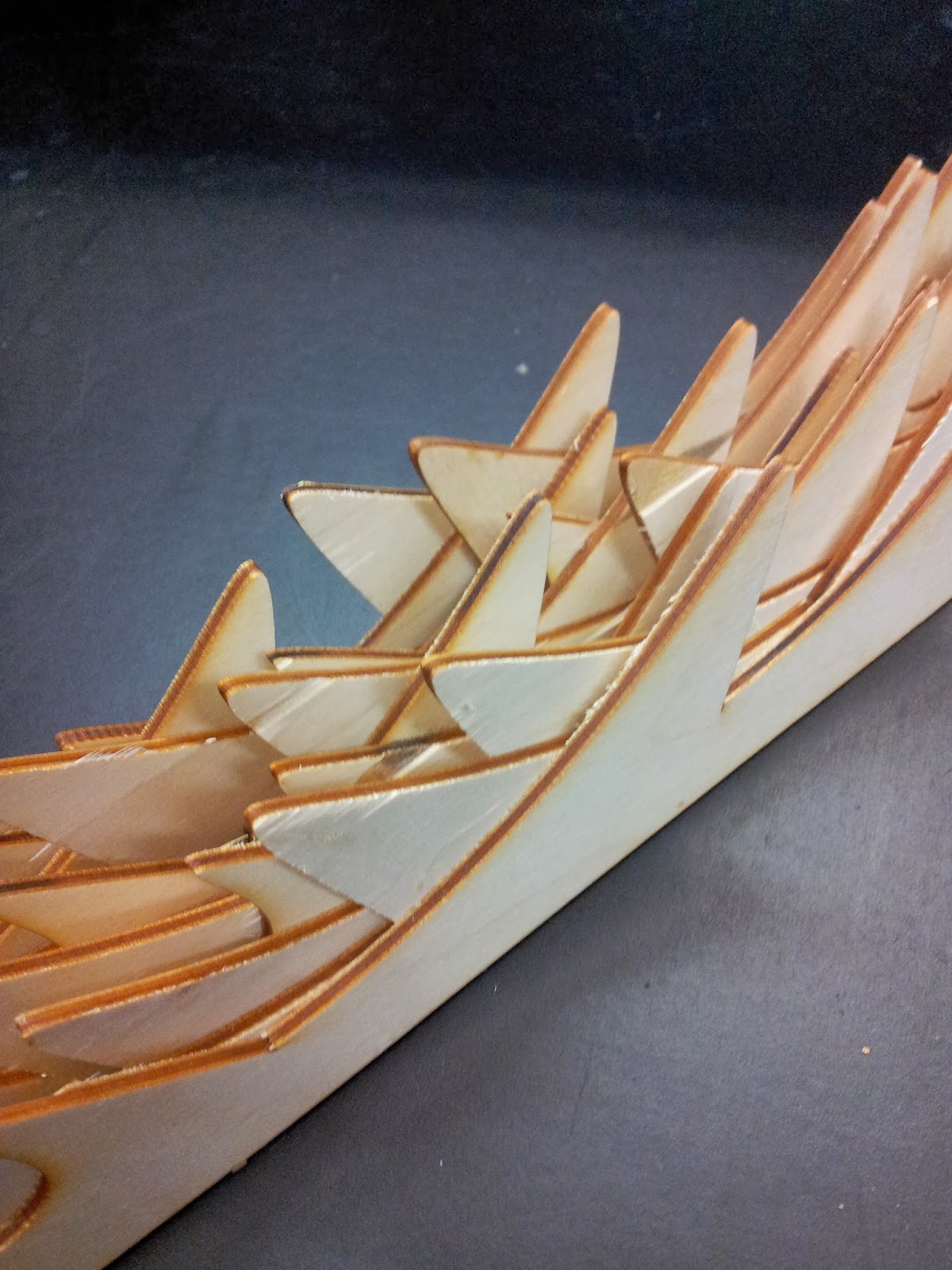

Myself and Jenny, for our individual project, have decided to print some of our Photoshop work as printed artwork for Bruntwood to place wherever they want. The designs are in-keeping with our group project with geometric shapes and structures, however the colour scheme is different. We have pushed ourselves out of our comfort zones by not using colour on the table - usually our main starting point in our textiles work. We have also had some spare time at the end of the project, so we thought we would use our initiative and create a collection of fabric samples too. If we had more time, we would have ideally liked to screen print these designs onto the table top as a feature - inspiration from Daniel Heath (immediately below).

Problems with producing the table

After sampling on the laser cutter last week, myself and Jenny tried to book back on the machine at the next available space to engrave the 18mm plywood. However, we came across our biggest problem in this project so far - there wasn't any space left until after the deadline! Adan the technician had a cancellation that same day, so there was a slight panic to gather materials together in time for the slot he could offer us. I managed to get the wood from home and get back to the workshop in time for the session, so it was a success, although it was very heavy! On beginning the session, Adan explained that we would not be able to cut through the 18mm plywood with the laser, as the thickest it could cut through is 6mm, although we would be able to engrave onto it still. We had to alter the design quickly in order to finish it within our given slot. In the short notice of being able to use the laser cutter, we didn't have any slate with us to engrave into for the centre of the table. We have had to change the design slightly so that only one 10cmX10cm tile will fit in the centre now - it is not ideal, and we would have liked more time on the machine to engrave better designs onto the slates, but there was a long waiting list after our session for cancellations, so we had to make the most out of a bad situation. Adan did however suggest that we could design the hole for the centre of the wood and he would be able to create a rebate for the slate to sit in using the CNC Router, making the surface flat and appropriate for use. I plan to revisit the Royal Exchange Theatre Workshop this week to finish off the table top, staining and varnishing it as planned. We will then find a way to secure the slate in place in the centre of the wood next week.

Stained Wood

Additional Work

Myself and Jenny, for our individual project, have decided to print some of our Photoshop work as printed artwork for Bruntwood to place wherever they want. The designs are in-keeping with our group project with geometric shapes and structures, however the colour scheme is different. We have pushed ourselves out of our comfort zones by not using colour on the table - usually our main starting point in our textiles work. We have also had some spare time at the end of the project, so we thought we would use our initiative and create a collection of fabric samples too. If we had more time, we would have ideally liked to screen print these designs onto the table top as a feature - inspiration from Daniel Heath (immediately below).